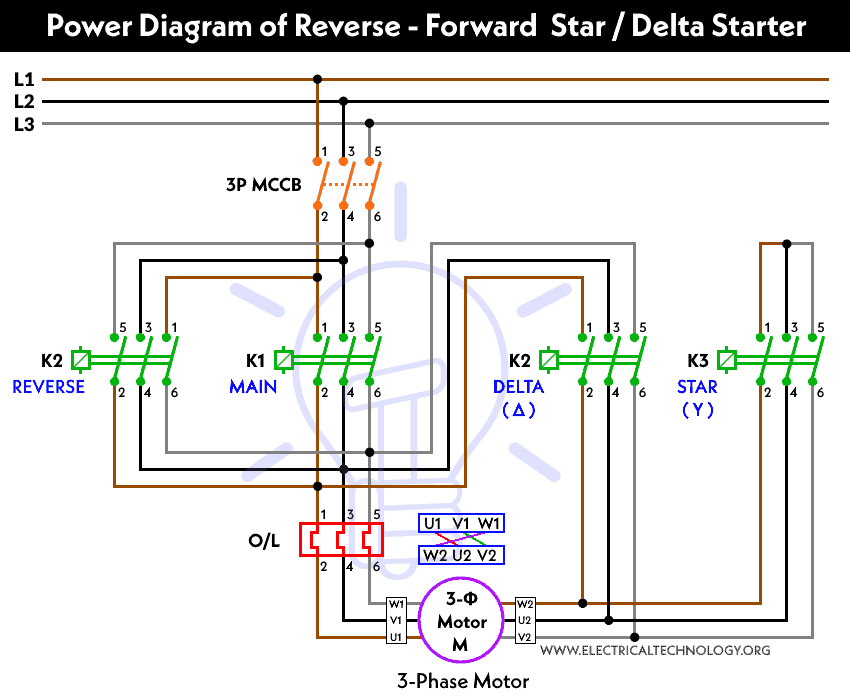

Normally DOL(Direct On-Line) starter is used to start the motor.

The Motor Starter is a device that is used to start and stop the motor to which it is connected. Therefore, Starter is needed to limit the starting current to avoid damage to the motor as well as other connected electrical equipment in the same line supply. It also generates a voltage dip on the supply line which might result in the malfunction of other connected electrical equipment.

This huge current can damage the motor windings. This current reduces as the motor achieves it’s running speed. Initially, it will take a huge amount(normally 5-8 times more than it’s rated) current. So, In this blog, we are going to see the What is Motor Starter, Types of Starter and Why do we need starters to start any motor?Īdditional to this we will also cover the basic conversion of this motor starter into PLC Programming using Ladder Logic.Īs we all know that when we supplied a 3-phase supply for the starting of induction motor. To drive this Electric Motor, we need Motor Starter. If you want to drive any mechanical equipment then you have to connect it with Electric Motor. The NPN transistor BD 139 drives the output from timer IC, this output pulse duration decides the speed of DC motor, by varying the VR1 resistor we can vary the pulse output of timer.In Electrical Engineering, the most basic topic is Electrical Motor. The diode D1 protects the DC motor from the back emf effect hence there is no output load effect rise. The DC motor is connected to the supply through DPDT ( double pole double through ) switch, by changing the switch position we can get forward and reverse rotation from the DC motor because this switch interchanges power supply polarity applied to the DC motor. In this website we already published about Speed control of DC motor with timer IC, here this circuit constructed for the basic motive to meet the forward / Reverse operation of DC motor with speed control.

0 kommentar(er)

0 kommentar(er)